Explore our latest innovations in crop care

Discover what's new...

A new generation of trailed sprayers

The new KARAN trailed sprayer

The new KARAN trailed sprayer offers tank capacities of 4,500, 5,200, 6,000 and 8,000 litres. It is equipped with steel and aluminum booms ranging from 18 to 45 metres.

KARAN is an efficient sprayer, designed to needs current and future crop protection challenges.

Thanks to advanced technical features and intelligent technologies such as EAGLE contour control, KARAN offers top-level performance. Equipped with the AUTOSPRAY system, it ensures optimal crop protection.

KARAN stands out for its exceptional comfort of use. Its maneuverability, ergonomics and high level of automation make every operation smoother and less demanding for the user.

The sustainability of KARAN is ensured by easy maintenance and high-quality components, thus ensuring increased reliability and longevity.

Spreading innovation: What’s new in our fertiliser range

AXIS & AXENT:

New OPTIPOINT PRO technology

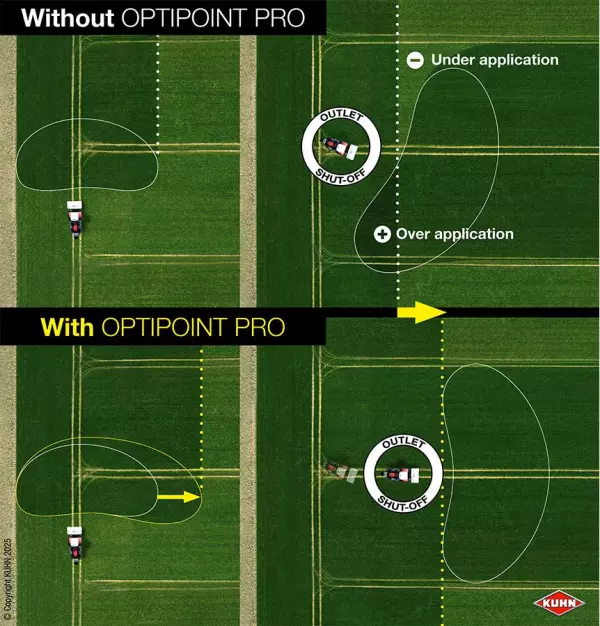

During fertilisation jobs, outlet opening and closing at headlands depends on the type of fertiliser, the working width, and the type of spreading disc. With some « fertiliser/working width » combinations, metering outlets close while the operator is already turning at the headland. This results in underdosing on the inside of the bend and overdosing on the outside.

Some AXIS and AXENT models will be equipped with the new OPTIPOINT PRO technology as of the 2026 season. This technology adjusts the spread fan when turning at headlands by increasing the working width towards the middle of the plot. The outlets are closed sooner, at the beginning of the headland turn. The spread fan does not pivot which means the right application rate is delivered all the way up to the headland.

No more under- or over-dosing on headlands!

AXIS 50.2:

New extension

A new 1,000-litre extension is available for AXIS 50.2 mounted fertiliser spreaders. This new option supplements the standard hopper capacity of 4,200 litres to provide a total load capacity of up to 5,200 litres of fertiliser. That’s around 4 tonnes of urea. The maximum payload remains 4,200 kg.

So, you can save time and money with less back-and-forth trips and stops for refilling.

Increase your productivity and reduce your operational costs!

New mechanical weeding equipment

Rotary hoe STARLINER: high-performance mechanical weeding!

The STARLINER rotary hoe is a new machine joining the KUHN mechanical weeding range. Designed to remove young weeds and break up slaking crusts, it offers a working width of 6.30 m. The STARLINER stands out for its high work output, with speeds of 12 kph to 25 kph. The machine’s versatility enables it to work in plots with many plant residues. Its simple and robust design allows for easy use and increased durability.

Other News

Our single-seed drills, 100% KUHN design and manufacture

For nearly 160 years, KUHN Châteaubriant has been a specialist in agricultural machinery. From design to marketing, our KUHN teams have buil...

Read

FIMA 2026: KUHN technologies recognized for their innovation

At the 44th edition of the International Agricultural Machinery Exhibition (FIMA), two new KUHN technologies were recognized in the Technica...

Read

New launches from KUHN North America factory

KUHN North America has unveiled an impressive new lineup of equipment designed to help farmers boost productivity, optimize daily operations...

Read