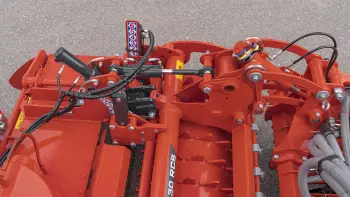

Quick and easy to couple/uncouple

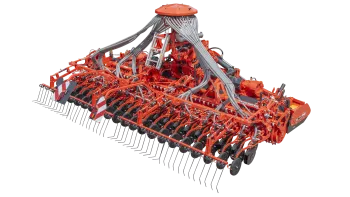

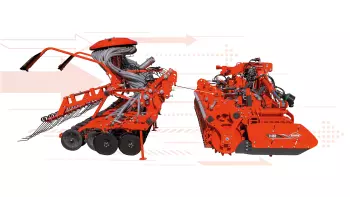

KUHN seeding bars can be equipped, depending on models and working widths, with Suffolk coulters (BTFR 1010), single discs (BTFR 1020), or SEEDFLEX 1000 (BTF and BTFR 1030) seeding units.KUHN power harrows feature specially designed attachment parts to facilitate coupling the seeding bar, with no tools required. They also have hydraulic tie rods that contribute to reduce overhang. In addition, the seeding bar can be pivoted to work solo with the power harrow, i.e., it is not necessary to remove the seeding bar