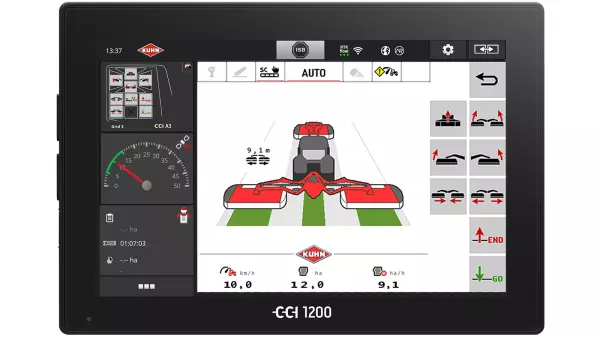

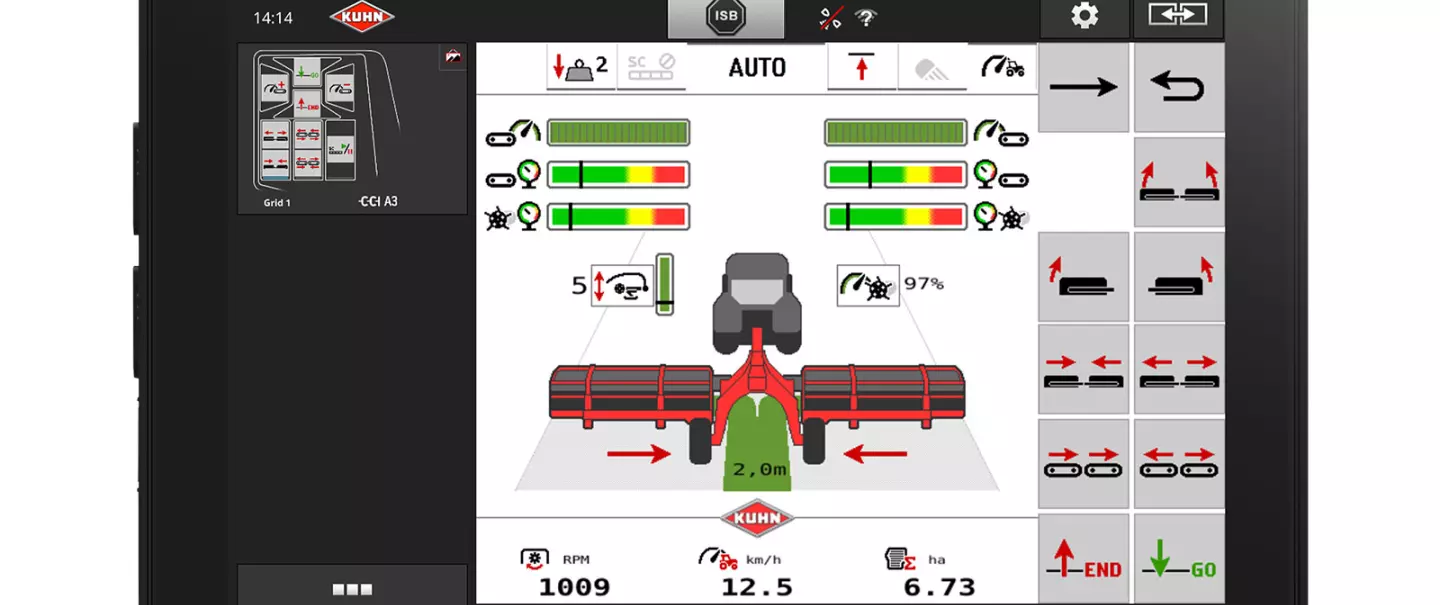

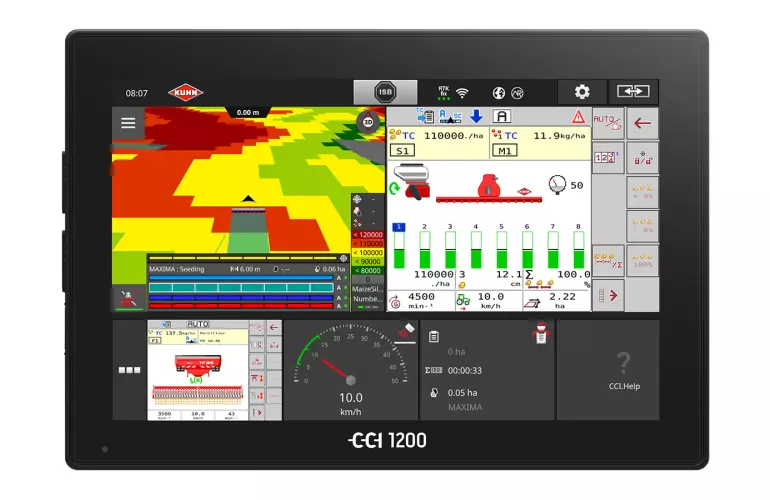

Brand-new, large-size, ultra high performance

The terminal has been developed with three priorities: increased performance, visibility and flexibility. These efforts resulted in a 30.5 cm (12.1") touchscreen terminal in the shape of a tablet, allowing the operator to display all of the essential information. The user-friendly, antiglare screen, offers excellent visibility even with the sun shining on it.