A multipurpose shredder for all orchards

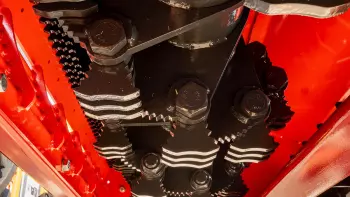

The TDP shredder can be attached in front position but also, when the tractor allows it, in rear position in reverse drive station. This is possible owing to the double free wheel integrated in the shredder's central gearbox. The latter ensures optimal power transmission allowing linkage to tractors of up to 150 hp. The rigid attachment makes it easy for branches delivered in large swaths to enter the casing.