| 5.10 | 5.60 | 5.60 | 5.70 | 6.10 | 5.70 | | | 5.70 | 5.70 |

| | | | | | 6.10 | 7.40 | | |

| 67 / 80 | 67 / 80 | 67 / 80 | 67 / 80 | 67 / 80 | 67 / 80 | 67 / 80 | 67 / 80 | 67 / 80 | 67 / 80 |

| Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year | Up to 1500 hours per year |

| 4.5 | 4.5 | 4.5 | 5 | 5 | 5 | 5.5 | 6.5 | 5 | 5 |

| 74 / 100 | 74 / 100 | 74 / 100 | 74 / 100 | 74 / 100 | 74 / 100 | 88 / 120 | 88 / 120 | 74 / 100 | 74 / 100 |

| Hydraulic pivot-mounted system with 116° slew | Hydraulic pivot-mounted system with 116° slew | Hydraulic pivot-mounted system with 116° slew | Hydraulic pivot-mounted system with 116° slew | Hydraulic pivot-mounted system with 116° slew | Double pivot-mounted hydraulic safety with 116° slew and outer boom | Hydraulic pivot-mounted system with 98° slew | Hydraulic pivot-mounted system with 98° slew | Hydraulic pivot-mounted system with 116° slew | Hydraulic pivot-mounted system with 116° slew |

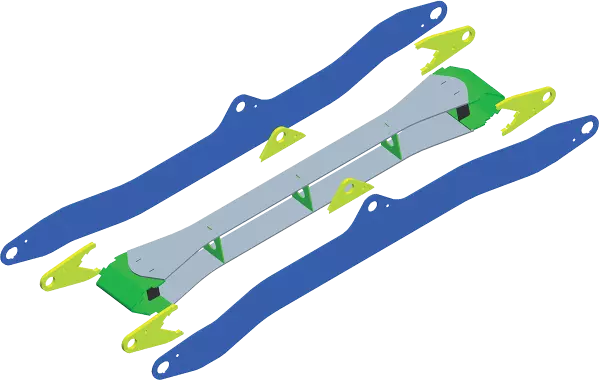

| Compass | Compass | Compass | Parallelogram | Parallelogram | Parallelogram | Compass | Compass | Parallelogram | Parallelogram |

| Straight arm | Straight arm | OPTIview semi-leading arm | OPTIview semi-leading arm | OPTIview semi-leading arm | MAXIview leading arm | Straight telescopic arm (stroke: 1 m) | Straight telescopic arm (stroke: 1.50 m) | Straight arm | OPTIview semi-leading arm |

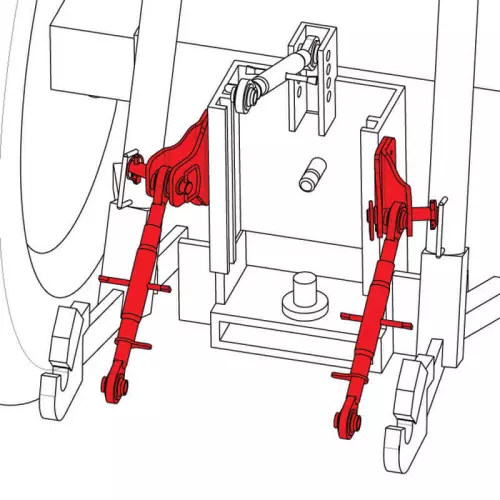

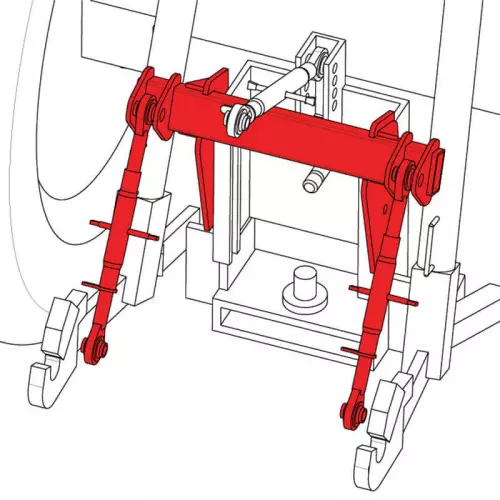

| 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 | 3-point cat. 2 and 3 |

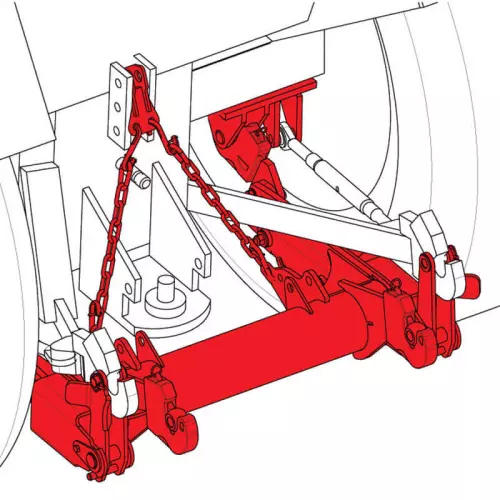

| Automatic hitch bar + 2 stabilisers with universal joints | Automatic hitch bar + 2 stabilisers with universal joints | Automatic hitch bar + 2 stabilisers with universal joints | STABI-LINK quick hitch axle mounted frame with brackets | STABI-LINK quick hitch axle mounted frame with brackets | STABI-LINK quick hitch axle mounted frame with ladder hitch. Please note that the chassis is secured to the rear axle yokes with a pin, not a quick-release clasp. | STABI-LINK quick hitch axle mounted frame with brackets and ladder hitch. Please note that the chassis is secured to the rear axle yokes with a pin, not a quick-release clasp. | STABI-LINK quick hitch axle mounted frame with brackets and ladder hitch. Please note that the chassis is secured to the rear axle yokes with a pin, not a quick-release clasp. | STABI-LINK quick hitch axle mounted frame | STABI-LINK quick hitch axle mounted frame |

Frame, main boom and outer boom with reconstituted very high yield steel structure – Main boom section 165 x 140 x 6 to 15 mm

Outer boom section 155 x 135 x 6 to 10 mm | Frame, main boom and outer boom with reconstituted very high yield steel structure – Main boom section 165 x 140 x 6 to 15 mm

Outer boom section 155 x 135 x 6 to 10 mm | Frame, main boom and outer boom with reconstituted very high yield steel structure – Main boom section 165 x 140 x 6 to 15 mm

Outer boom section 155 x 135 x 6 to 10 mm | Frame, main boom and outer boom with reconstituted very high yield steel structure – Main boom section 165 x 140 x 6 to 15 mm

Outer boom section 155 x 135 x 6 to 10 mm | Frame, main boom and outer boom with reconstituted very high yield steel structure – Main boom section 165 x 140 x 6 to 15 mm

Outer boom section 155 x 135 x 6 to 10 mm | Frame, main boom and outer boom with reconstituted very high yield steel structure – Main boom section 175 x 150 x 6 à 26 mm

Outer boom with variable section: 172 x 144 to 108 x 108 x 6 to 16 mm | Frame and main boom with reconstituted very high yield steel structure

Main boom section 175 x 170 x 6 to 20 mm

Outer boom tubular section 150 x 150 x 6 mm | Frame and main boom with reconstituted very high yield steel structure

Main boom section 175 x 170 x 6 to 20 mm

Outer boom tubular section 150 x 150 x 6 mm | Frame, main boom and outer boom with reconstituted very high yield steel structure

Main boom section 165 x 140 x 6 to 15 mm

Outer boom section 155 x 135 x 6 to 10 mm | Frame, main boom and outer boom with reconstituted very high yield steel structure

Main boom section 165 x 140 x 6 to 15 mm

Outer boom section 155 x 135 x 6 to 10 mm |

| As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard |

| As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard | As standard |

| | | | | As standard | | | As standard | As standard |

| 3.57 | 3.87 | 3.87 | 3.78 | 3.95 | 3.94 | 3.78 | 3.78 | 3.78 | 3.78 |

| 1 820 | 1 840 | 1 865 | 1 960 | 1 995 | 2 305 | 2 060 | 2 130 | 2 175 | 2 185 |

| - | - | - | 2 160 | 2 195 | | 2 290 | 2 360 | | |