For almost 200 years, we have been manufacturing agricultural machinery and parts, which gives us unique know-how to guarantee the quality of all our products.

There is nothing better than a KUHN part for a KUHN machine. Because your satisfaction is our priority, we pay attention to each stage in the manufacture of our parts.

From raw material to field testing

Our parts are designed to provide maximum service life, reducing replacement frequency and costs.

By reducing the replacement frequency of your wearing parts, and by opting for parts that ensure optimal agronomic results, you are sure to obtain the best service life/price ratio.

Original parts are manufactured to perfectly match your KUHN machine to guarantee proper operation and ensure its durability over time.

Benefit from the support and expertise of our 4,500 KUHN authorized dealers around the world.

Why choose genuine KUHN parts?

1. Our specifications include in particular:

- Operating and working conditions

- Work quality objectives

- Minimum expected service life

- Power and fuel consumption reduction objectives

- Part replacement time objectives

Find all genuine parts on MyKUHN

Connect to MyKUHN2. Conformity of materials used and heat treatments

To verify the conformity of materials, processes and heat treatments we use ultra-modern measuring tools:

To analyze and validate steel grades:

To control the steel grade used, we use a spectrometer, which allows us to analyse a part sample by determining the percentage of 21 chemical elements present in the sample.

We select a steel grade adapted to each wearing part; many are made of boron steel to allow for optimalheat treatment.

We verify the steel grade used to ensure consistent quality, regardless of the manufacturing batch.

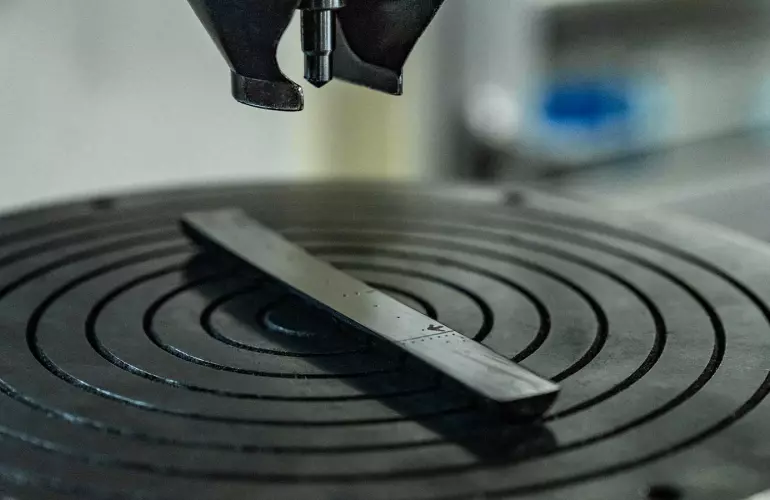

To validate the hardness:

To test the hardness of steel (Rockwell HRc), a diamond point is pressed against the surface of a part with a standard force. The size of the resulting indentation determines the material's hardness.

Thanks to the use of boron steel and heat treatment, the hardness of our rotary harrow tines averages 50HRc. Some adaptable parts, often without heat treatment or poorly treated, have a hardness lower than 30HRc, which compromises their durability.

To validate the manufacturing process:

Using a microscope allows you to zoom in on an area of the part to analyse its structure.

This tool also allows you to observe, for example, how tungsten carbide plates are brazed onto parts to assess the quality of the brazing and ensure proper adhesion over time, without the risk of the plates detaching.

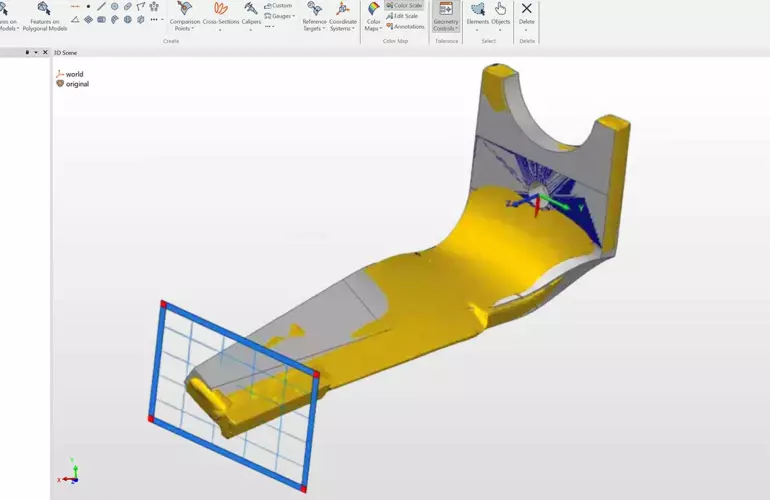

3. Dimensional compliance

Although often similar to the naked eye, it's with a 3D scan that we can see the profil differences between a genuine KUHN part and an adaptable part.

An incorrect dimension, however small, can have detrimental consequences for the machine. For example, a non-genuine power harrow tine profile varying by just a few millimetres will increase power consumption and fuel consumption, as well as put additional strain on the machine's drivetrain.

Superposition of a standard original KUHN rotary harrow tine and an adaptable carbide rotary harrow tine. The blue insert corresponds to the section found on the right image.

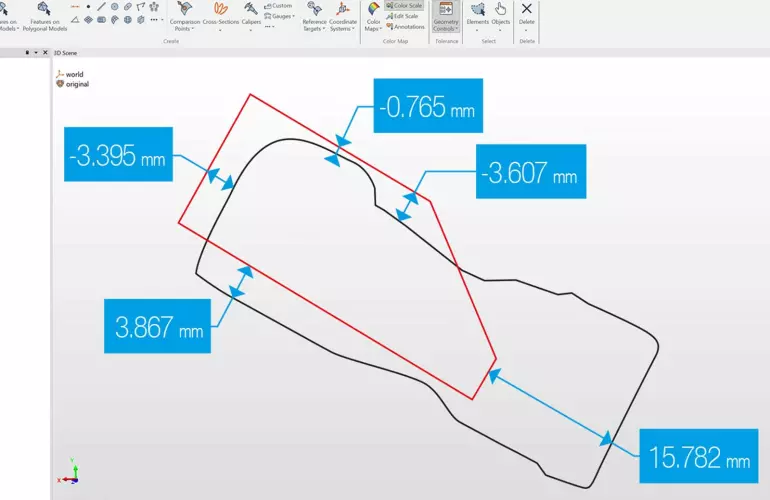

In red the section of the original KUHN part and in black the adaptable part with the distance in mm measured between the two parts.

Measurements taken using the 3D scan show that there is indeed a gap between the KUHN part and the non-origine part, with a gap of up to 15.782 mm between two rotary harrow tines.

4. Validation on a test bench

We validate and compare our parts to competing parts on a test bench according to well-defined criteria and objectives. Through bench tests, we replicate the stresses that parts undergo during operation.

For example, we measure the tine’s resistance to fatigue on our forage harvesting machines, which allows us to determine their service life.

KUHN tines, designed in high-end spring steel, resist on average 120,000 cycles before breaking, while a non-genuine part designed in low-end spring steel will resist only 10,500 cycles on average.

Test conclusion: with resistance multiplied by 11.4 on average, KUHN tines far outperform adaptable tines.

5. Validation and comparative test under real conditions

We constantly carry out comparisons of wearing parts in field conditions. To do this, we select clients across the world who work in the most extreme conditions to test different technical solutions (part profile, material, competing parts, etc.).

Put to the test in 2022 in Denmark, the DURAKARB plough point worked 190 hectares in heavy-duty conditions, without reaching its wear threshold.

Conclusion

We make sure to offer the best value for money. Genuine KUHN parts are perfectly suited to your machines and their use. They ensure optimal adaptation to their operating conditions and are built to last. This provides greater performance and peace of mind at work.

Choosing KUHN parts is choosing optimal quality, increased longevity, improved profitability, safety, and the support of our authorized dealers.

Find all genuine parts on MyKUHN

Connect to MyKUHN