Plough shares

The plough share is a wearing part essential for soil penetration and cutting the furrow slice. There are different types of shares, especially the pointed share and the knife coulter. ...

The plough share is a wearing part essential for soil penetration and cutting the furrow slice. There are different types of shares, especially the pointed share and the knife coulter. ...

Ploughs consist of many wear parts, including points, shares, mouldboards, shins, landsides, blade coulters, skimmers, and landside points and heels.

Points are wearing parts fitted to shares for improved soil penetration. Points are the most frequently replaced wearing part. Plough points also protect and reduce the wear of other plough parts.

KUHN points are forged in a 1500-ton press at our Châteaubriant factory, in the west of France. Mastery in dropforging and heat treatment ensures excellent wear resistance in any conditions. The metal is thicker in the high-wear areas of the point, i.e., the extremities.

The shape of KUHN plough points helps to keep fuel consumption down and create uniform wear, on any terrain.

These points are specially designed for stony plots with a rocky bottom.

These points are specially designed for stony plots with a rocky bottom.

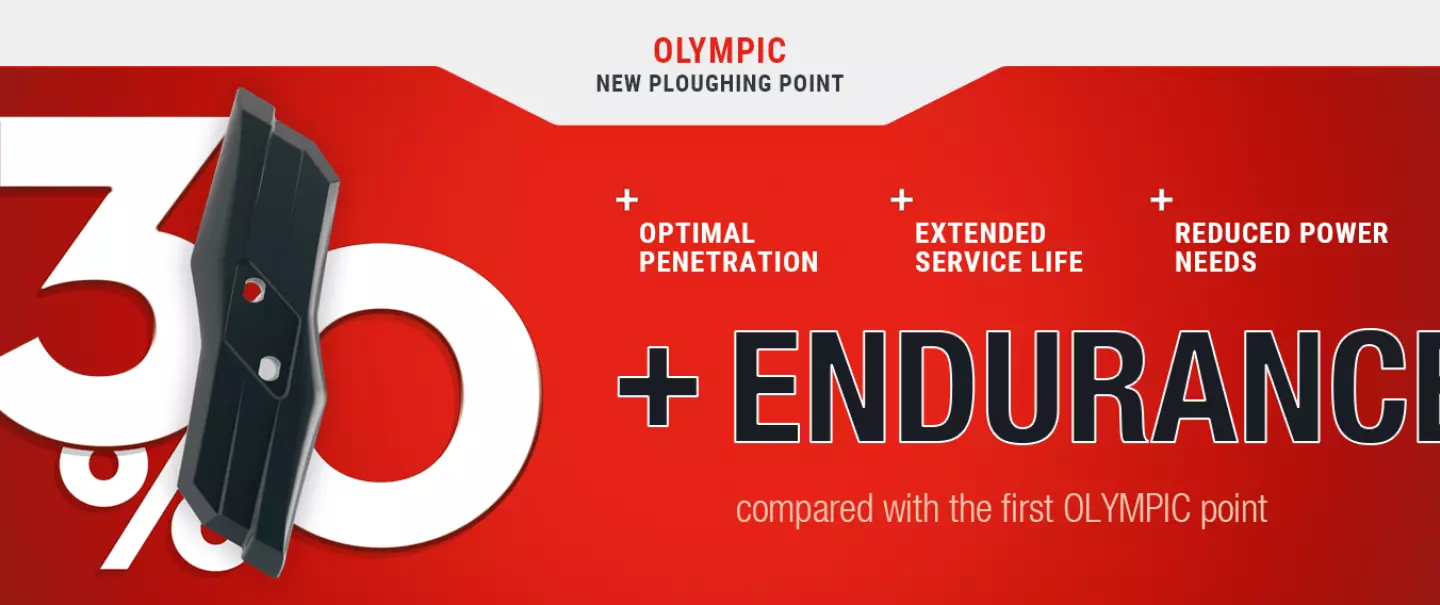

A new generation of OLYMPIC points has been launched in 2024. This point, whose thickness has been reinforced in the most exposed areas, offers a lifespan of more than 30% compared with the previous generation. Here are its main features:

And always the guarantee of an original part, developed and dedicated to KUHN ploughs.

Discover the new generation of OLYMPIC points

Discover the new pointsThe KUHN range includes SUPER-MARATHON points reinforced with carbide plates. This enables you to plough a larger surface area compared to a standard point.

The share’s job is to cut into the land to the depth you want. The soil slides over the share to the shin and then onto the mouldboard to mix in all crop residues.

Shares are available with DURAKARB technology carbide plates. Their service life lasts 4 times longer than shares without carbide plates.

Find out more about carbide parts

Discover our range

More about carbide partsChecking regularly the condition of the landside point is essential to extend its service life. When replacing it, it is also important to check the condition of the plough share and the frog as well as their fasteners. An incorrect alignment of the landside point can lead to premature wear of other plough parts, hence the importance of promoting parts designed and manufactured for the machine. In choosing KUHN parts you optimize your plough’s performance and reduce maintenance costs.

The skimmer share is one of two parts that make up the skim coulter. Its main function is to cut a strip of shallow land, prior to the main plough share lifts and turns over the rest of the soil with the mouldboard. The skimmer prepares the land by burying in crop residues and weeds to facilitate their decomposition and enrich the soil with organic matter. The skimmer share also contributes to improve ploughing quality by reducing the quantity of soil sticking to the mouldboard.

The shin plays a crucial role in preparing the soil and then guiding the earth towards the mouldboard. This is why KUHN pays particular attention to its manufacturing in its factory where the ploughs are produced in western France.

Triangular in shape, the shin is placed before the mouldboard to receive the flow of soil before turning it over. It serves to cut the soil vertically, thus facilitating soil cultivation and reducing plough resistance. It improves soil penetration, particularly in compact or clayey soils. Using a shin in good condition helps minimize tractor fuel consumption and improves ploughing quality.

The shin wears out more quickly than the mouldboard, its lower cost compared to that of the mouldboard allows for reduced maintenance costs.

The landside is a fundamental element of the plough. Positioned behind the ploughshare, its main function is to stabilize and control the working depth of the plough by preventing the mouldboards from sinking too deeply. This action facilitates the ploughshare and mouldboard work, especially in heavy and compact soils. Using a landside in good condition improves ploughing quality.

The mouldboard is the most important part of a plough. Its function is to turn over all the soil and crop residues to prepare the next crop thanks to its curved shape.

The mouldboard is a wearing part subject to significant stress, particularly abrasion due to constant contact with the ground. It is therefore crucial to choose mouldboards made from high-quality, heat-treated steel to increase its strength and durability. This is the case with KUHN mouldboards designed in our Châteaubriant factory.

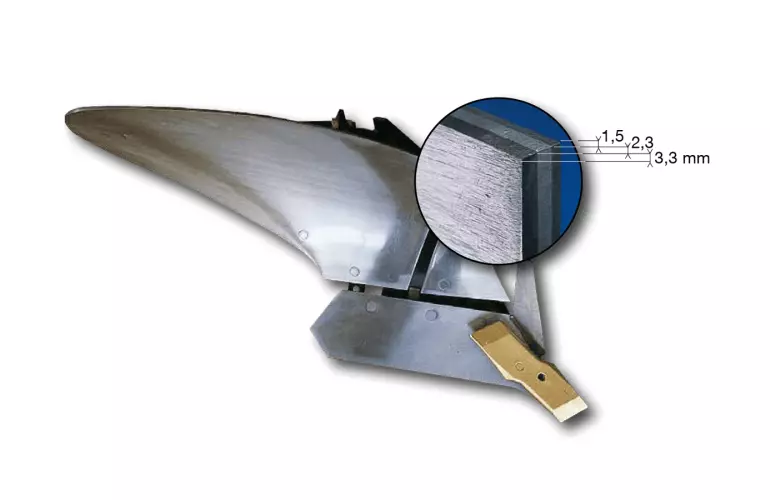

The mouldboards and shins benefit from TRIPLEX technology, which involves providing the part with uneven layers of greater thickness on the wear face, therefore a greater wear reserve compared to conventional shins and mouldboards. The service life is extended to promote the service life / price ratio.

The shin’s dimensions ensure very good protection of the mouldboard and the frog. This part helps reduce costs by limiting wear and therefore the frequency of replacement of the mouldboard.

Different types of original KUHN bodies are available. Whether helical scandinavian, slatted or helical, the bodies are designed to meet the different cultivations and techniques used throughout the world.

The plough bolt is an essential spare part for the safety and performance of the plough. It secures the various plough parts, such as the share, mouldboard, landside, and skimmer. A defective or improperly tightened bolt can cause these parts to shift or become lost, compromising the quality of soil cultivation and even causing significant damage to the plough. Bolt compatibility is crucial: it is recommended to use KUHN bolts to ensure the safety and durability of your plough.

Register on MyKUHN and enter your plough machine using its serial number to find parts diagram. Registration is free and easy.

At MyKUHN, you can find parts for your machine by consulting:

You can select your parts and sent your cart to your dealer.

Find all the parts and the catalogue directly on MyKUHN.

Subscribe quickly and for free

Go to MYKUHN