KUHN Baler Automation awarded ‘Technological Innovation’ at FIGAN 2025

The KUHN Baler Automation system has been awarded ‘Technological Innovation’ by the FIGAN 2025 Technological Innovations and Improvements Competition jury.

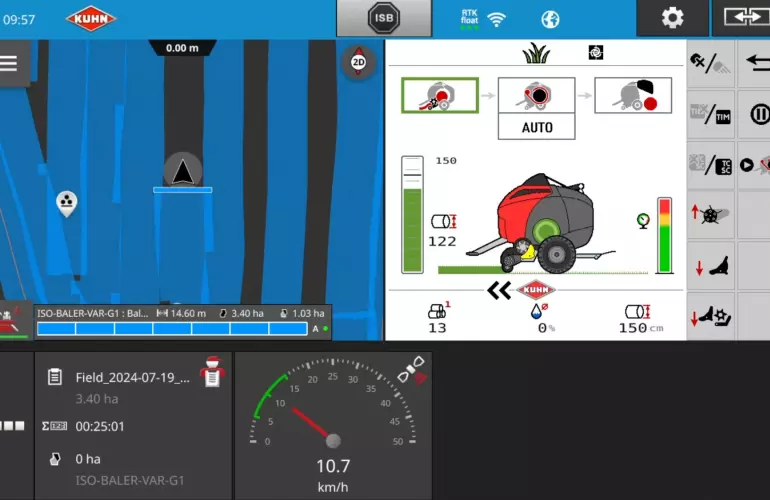

The KUHN Baler Automation system has been recognised for increasing the profitability of the farmer's baling operations, while enhancing bale quality and operator convenience. It also makes KUHN VB 7100 balers the first Section Controlled balers in the world with a GPS automated pick-up, and the first round balers with Task Controller geo-based.

KUHN Ibérica is proud of this recognition at the 17th edition of the International Fair of Animal Production (FIGAN).

The competition rewards the developments of those companies in the sector that invest in Research, Development and Innovation, selecting the products that stand out for their technological contribution, innovation and performance in terms of market needs.

What is the KUHN Baler Automation system?

Task Controller Section Control (TC-SC)

The TC-SC function allows VB 7100 series balers to be equipped with a GPS automated pick-up. The pick-up is only down when there is crop left for baling, and is automatically raised when turning onto the headland or if an already worked area is passed again. This improves the operators’ comfort throughout the long working day and reduces machine wear.

In addition, the function allows:

- Operate without the need to pre-load a field map or swath map and without complicated GPS settings before starting up

- Set the section width as the width between the swath (width of the rake that has passed previously)

- Determine and record the unworked area (on the tractor terminal displayed in grey) and the worked area (in blue)

Tractor Implement Management (TIM)

With Tractor Implement Management (TIM) the VB 7100 baler controls the tractor and the entire baling cycle is automated. Operators can constantly get the most out of their tractor and baler, while enjoying complete comfort.

This function comprises:

Other functionalities of KUHN Baler Automation:

- Task Controller basic (TC-BAS) and geo-based (TC-GEO): The tasks are recorded, documented and mapped with all related information, such as number of bales, customer and field information, yield and bale weight. In this way, an accurate report is automatically created for the company’s management.

- Auxiliary Control (AUX-N): The baler can be controlled directly via the CCI A3 joystick with its softkeys.

All intelligent electronic and automation solutions are available on the VB 7100 series round balers. These are also the first KUHN round balers equipped with a completely new user interface, which further facilitates easy and pleasant operation.

In conclusion, the main advantages of this system are:

- Improved ergonomics and operator comfort.

- Maximum performance of the tractor / baler combination

- Less wear and tear on the machine

- Simplified and optimised task and customer management

- More data and more accurate knowledge of the yield per field

- Easy data transfer

- Easier farm management

- Increased business profitability

“KUHN BALER AUTOMATION” system

Other News

Shredding large areas is no problem!

The BP 8402 PRO is a versatile shredder that works a width of up to 8.40 metres, ideal for users looking for high work output.

Read

Focus on some of the 2025 highlights

2025 was a year of innovation and success. Here are some of the highlights.

Read

More innovations for wine growers, arborists, and landscape maintenance

Read