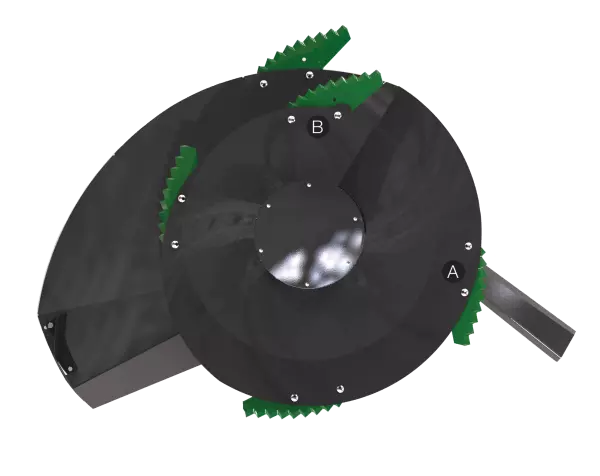

Cone-Style Auger & Kicker Design

Cone-style augers provide superior feed movement for faster, more complete mixing and processing. The smooth, continuous auger flighting (1) creates a rolling feed action that improves mixing. The top cover of the auger has a steep angle to aid in bale movement when processing round bales and to prevent feed from sitting on top of the auger between mixes. The swept back, bolt-on kicker (2) provides a fast and even discharge. The new kicker mount design is stronger and built to withstand the harshest resistance. Each lead flight is equipped with a cast iron scraper (3) that pulls material away from the tub walls into the auger for a better overall mix. Both the kicker and scraper are bolt-on attachments, making replacement very easy to save you precious time.