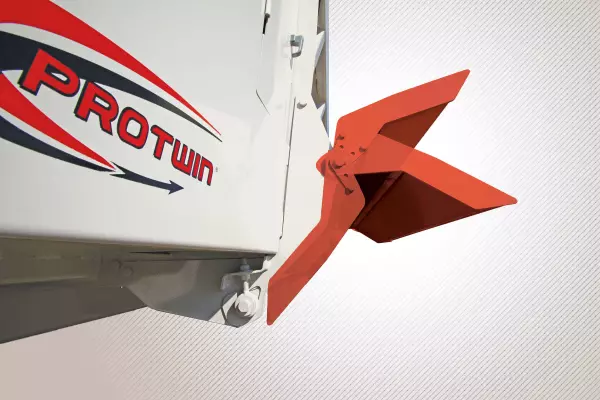

ProTwin Design

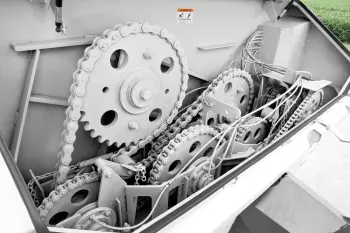

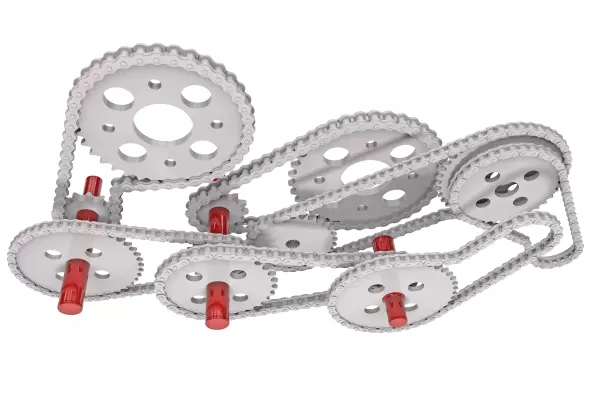

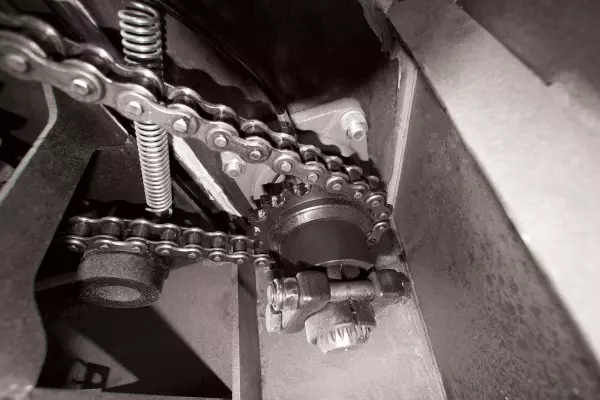

The raised, right auger moves material rearward to keep the load level. The left, lower auger moves material forward to continuously feed the discharge door.

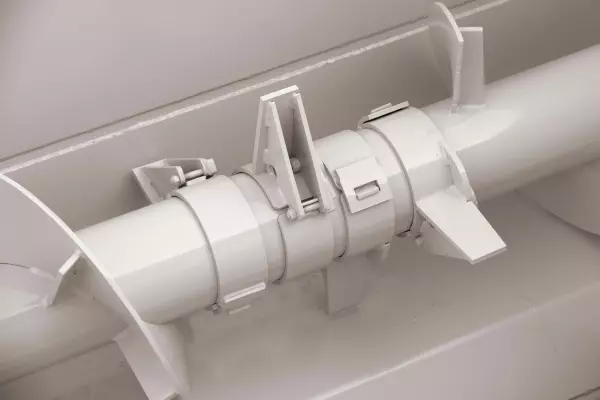

- Consistent Flow to the Discharge

The steep, slanted sides help provide a reliable material flow, continuously feeding material down to the augers. Combined with the unique auger design, this helps ensure constant delivery of material to the swinging hammer discharge. - Eliminates Bridging

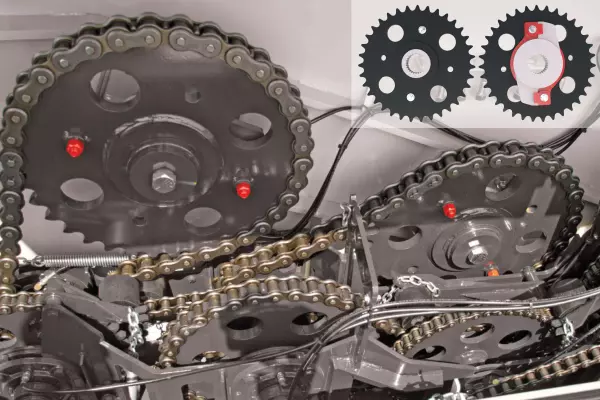

The well-proven, twin-auger design eliminates material bridging. The two augers work together to create a bidirectional flow that provides constant agitation and steady movement, even with the most challenging materials.