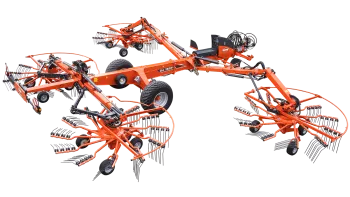

Exclusive: 4 rotors 100% hydraulic

One hour less maintenance, one hour more windrowing!

The rotors are driven hydraulically by hydraulic pumps driven by a single transmission to minimise maintenance. Forget about the daily greasing of secondary transmissions. You save up to one hour compared to a mechanically driven rake of the same size. This can make a difference when rain is threatening and the crop has to be brought in quickly. This reduces the need for maintenance.

Other benefits include smooth, quiet operation and minimal wear.

The hydraulic unit of the GA 13231, GA 14231 and GA 15231 rakes is positioned on the swivelling headstock of the machine frame. This ensures that the primary transmission is always perfectly aligned with the tractor, even in tight turns.

In addition, the PTO speed can be modified from the cab for perfect adaptation to the fodder type and volume. You can choose between two speeds: 1,000 or 750 rpm to save fuel.

The rotors are driven hydraulically by hydraulic pumps driven by a single transmission to minimise maintenance. Forget about the daily greasing of secondary transmissions. You save up to one hour compared to a mechanically driven rake of the same size. This can make a difference when rain is threatening and the crop has to be brought in quickly. This reduces the need for maintenance.

Other benefits include smooth, quiet operation and minimal wear.

The hydraulic unit of the GA 13231, GA 14231 and GA 15231 rakes is positioned on the swivelling headstock of the machine frame. This ensures that the primary transmission is always perfectly aligned with the tractor, even in tight turns.

In addition, the PTO speed can be modified from the cab for perfect adaptation to the fodder type and volume. You can choose between two speeds: 1,000 or 750 rpm to save fuel.