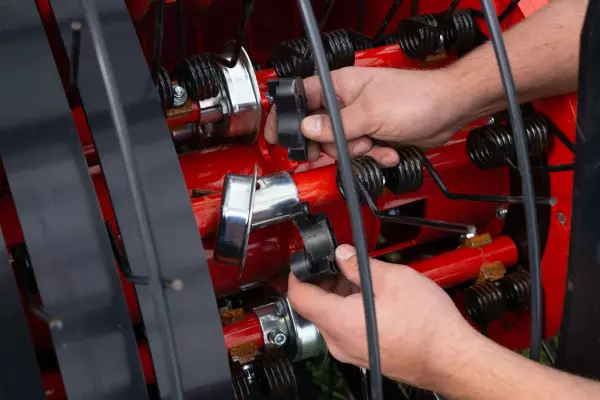

High-Capacity Pickups with Integrated Frames

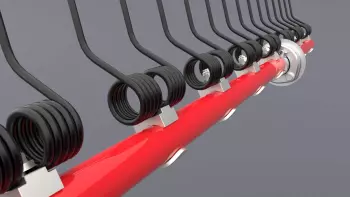

Commercially designed pickups treat crop gently yet are built and tested for extreme use. The central cam design with large heavy-duty sealed cam followers provide extra-long life even in the toughest conditions. KUHN high-capacity pickups are designed and built with integrated frames to improve the strength and durability of the pickups and keep the machine looking clean as there is no place for crop to catch and build up.