Made to last

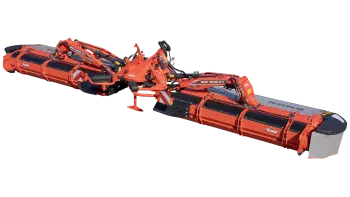

The GMD 9530 RV features a 100% mechanical power transmission system.

The swathing augers and cutter bars are driven separately by cardan shaft and gearbox resulting in a high-capacity and very robust machine, even in difficult conditions with heavy, dense fodder. The automatically resetting cam clutches and shear bolts, in the side gearboxes that drive the augers and cutter bar, secure all machine components while ensuring optimum working comfort and efficiency.

The swathing augers and cutter bars are driven separately by cardan shaft and gearbox resulting in a high-capacity and very robust machine, even in difficult conditions with heavy, dense fodder. The automatically resetting cam clutches and shear bolts, in the side gearboxes that drive the augers and cutter bar, secure all machine components while ensuring optimum working comfort and efficiency.