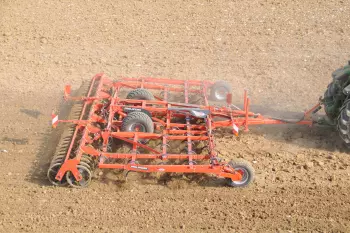

The PROLANDER enables seeding in front of the roller using either a front-mounted hopper kit or the SH 600 seed drill. As a cost-effective alternative for cereals, tine seeding with a front hopper kit ensures excellent soil penetration using the 50 mm point.

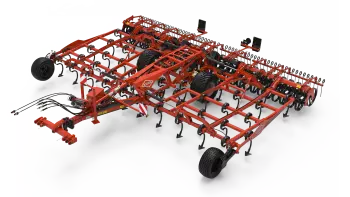

By combining the PROLANDER with a front-mounted hopper, stubble cultivation and seeding, either in front of the roller or at the tine, can be carried out in a single pass, optimising both time and establishment costs. This combination is the ideal solution for farms seeking efficiency and profitability. PROLANDER 6000 and 7500 can be equipped with the SH 600 small seed drill for seeding plant cover crops (mustard, phacelia, clover, ray grass, cereals) while stubble ploughing.

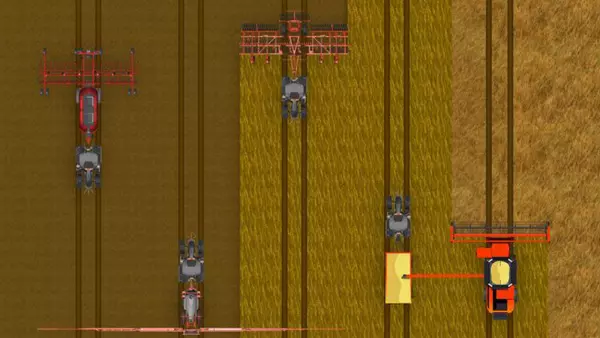

Crop covers are recognised for their agronomic, environmental and economic benefits. You can achieve time savings of 50% compared with a conventional establishment system (stubble cultivation + sowing + rolling).

The SH 600, with a 600-litre hopper capacity, is equipped with the same distribution system as our other seeders for increased seeding accuracy. The splash plates are positioned in front of the roller for an even distribution and optimal soil to seed contact.

Simple and precise settings are made from the cab via the QUANTRON S-2 box that enable you to:

- Modulate the seed rate manually or electronically by GPS;

- Monitor the seed level, blower and metering unit speeds.

- The PROLANDER with the SH 600 seed drill can help you acheive high work rates and low seeding costs.