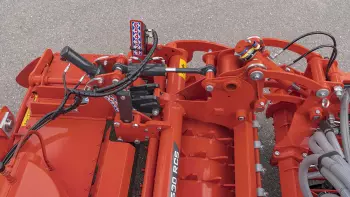

A specially designed frame to fit a seeding bar

KUHN RCS power harrow models are designed to be fitted with a seeding bar. The seeding bar fits onto the power harrow's roller frame. This configuration places the centre of gravity closer to the tractor, limits overhang, and reduces the power requirement for lifting the combination. It also improves work quality by providing high stability, excellent ground following, and a constant seeding depth, irrespective of the power harrow's working depth.