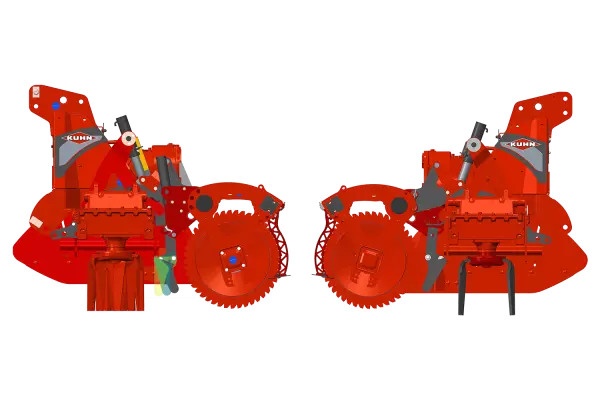

The seed drill mounted onto the roller frame

When coupled with a seeding combination, the power harrow depth and the seeding depth work completely independantly of each other. This is because the drill in mounted on the roller frame. This also increases stability, and guarantees accurate seed placement. These power harrows are designed to work with both pneumatic and mechanical seed drills.