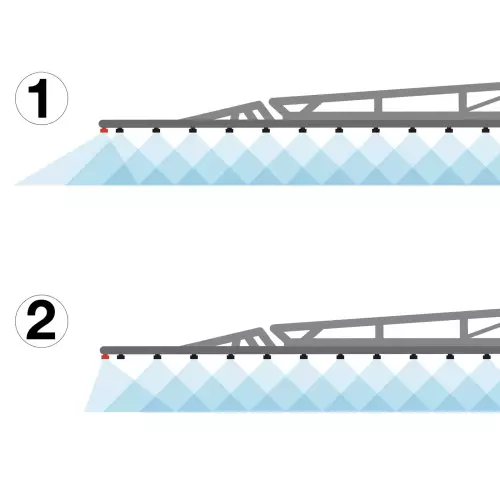

EAGLE: keeping the boom at the height of your expectations!

With the EAGLE contour control system, KARAN can operate at speeds of up to 25 km/h.

This advanced technology package automatically adjusts and actively controls the boom, even under changing crop conditions or varying types of terrain, situations frequently encountered during spraying operations. Highly responsive, the EAGLE system can operate as close as possible to the target to be sprayed (from 30 cm height).

As a result, application height is consistently maintained under these variable conditions, even at high speeds, improving spray accuracy (overlap, drift, etc.) and delivering outstanding driving comfort in the field.

This advanced technology package automatically adjusts and actively controls the boom, even under changing crop conditions or varying types of terrain, situations frequently encountered during spraying operations. Highly responsive, the EAGLE system can operate as close as possible to the target to be sprayed (from 30 cm height).

As a result, application height is consistently maintained under these variable conditions, even at high speeds, improving spray accuracy (overlap, drift, etc.) and delivering outstanding driving comfort in the field.