Limit downtime

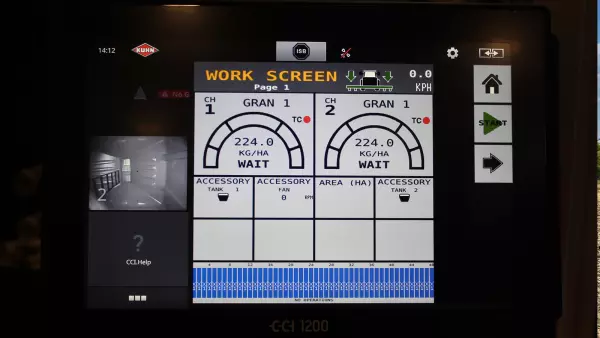

You wish to sow wheat at 180 kg/ha on an area of 220 ha in a single day? It is possible and you will only need 3 stops to reload the hopper.

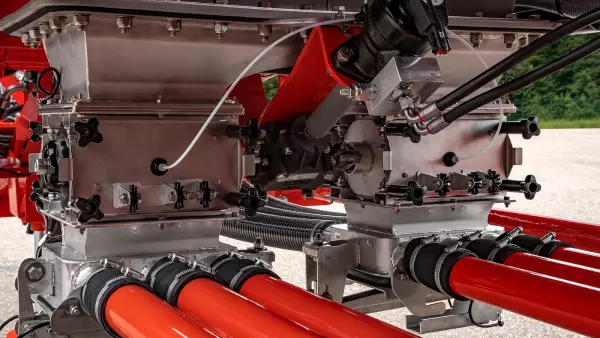

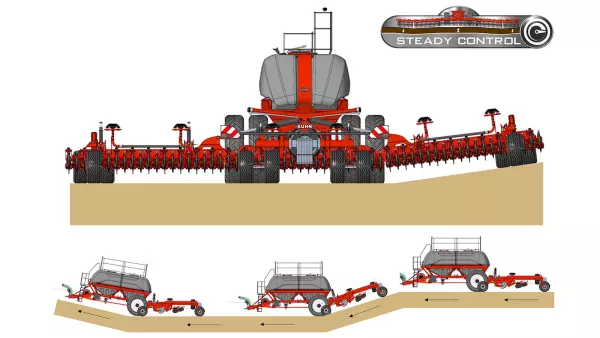

With its 13,000 litre hopper and a working width of 12 m, the ESPRO RT 12000 RC allows sowing large areas in a minimum of time. The loading auger, directly mounted on the machine, reduces the time spent on reloading. Thanks to a high filling rate, only 15 to 20 minutes are needed to fill the hopper. If you want to change varieties or species, simply empty the remaining seeds by sliding the loading auger under the metering units.

The ESPRO RT 12000 RC also has a low pull power requirement and can therefore be used with a tractor from 280 hp. Its speed can reach up to 20 kph.

With its 13,000 litre hopper and a working width of 12 m, the ESPRO RT 12000 RC allows sowing large areas in a minimum of time. The loading auger, directly mounted on the machine, reduces the time spent on reloading. Thanks to a high filling rate, only 15 to 20 minutes are needed to fill the hopper. If you want to change varieties or species, simply empty the remaining seeds by sliding the loading auger under the metering units.

The ESPRO RT 12000 RC also has a low pull power requirement and can therefore be used with a tractor from 280 hp. Its speed can reach up to 20 kph.