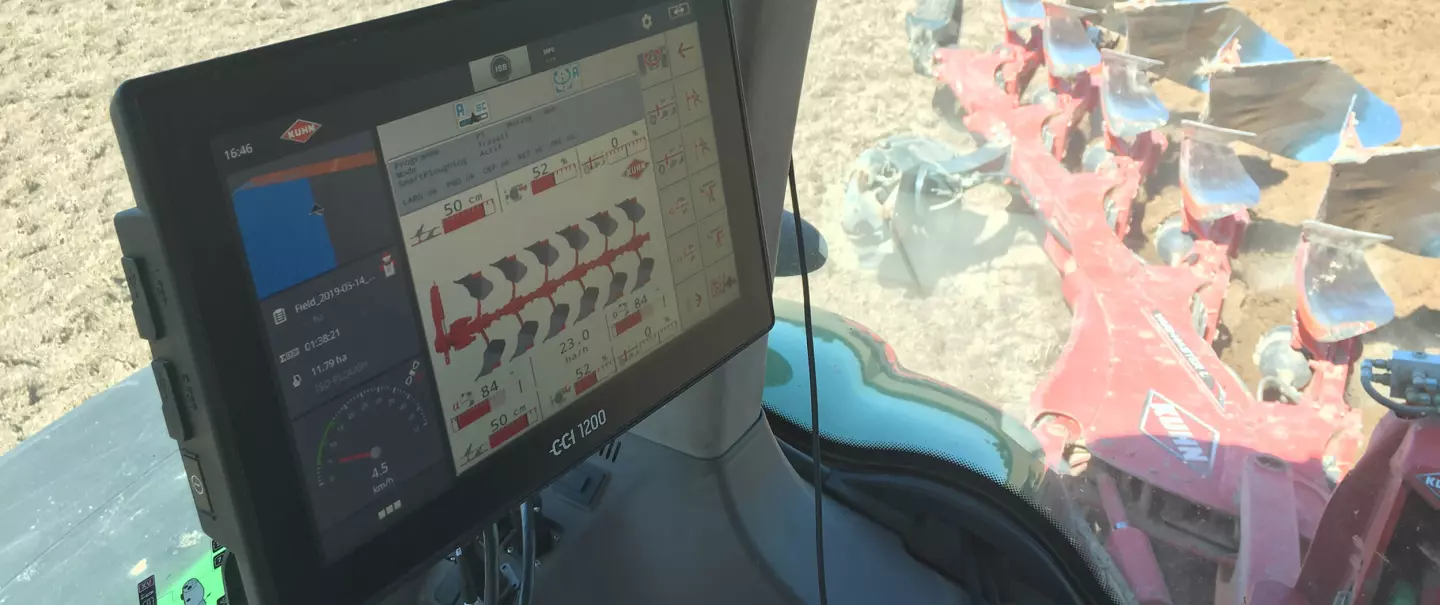

Adjust your plough from the ISOBUS terminal

Smart Ploughing refers to all the functions of the plough available on the Isobus terminal in the cabin. All adjustments are performed from the Isobus terminal: working width, offset, working depth, angle. The various adjustment scenarios, depending on the crop to be planted, (wheat, maize, beets, etc.) are saved so that they can be reproduced without losing any time at entry to the field. It is possible to modify them in real time for perfect adaptation to heterogeneous conditions.

A single Isobus console replaces a multitude of control boxes to simplify the user's work while increasing their level of comfort.

For more ergonomics, the settings can be adjusted using an auxiliary joystick so that the functions that are useful to you can be at hand.

A single Isobus console replaces a multitude of control boxes to simplify the user's work while increasing their level of comfort.

For more ergonomics, the settings can be adjusted using an auxiliary joystick so that the functions that are useful to you can be at hand.