An ultra-robust design

KUHN has been a leader in the design and manufacture of ploughs for decades. This experience has made it possible to develop increasingly efficient ploughing bodies to ensure you better profitability.

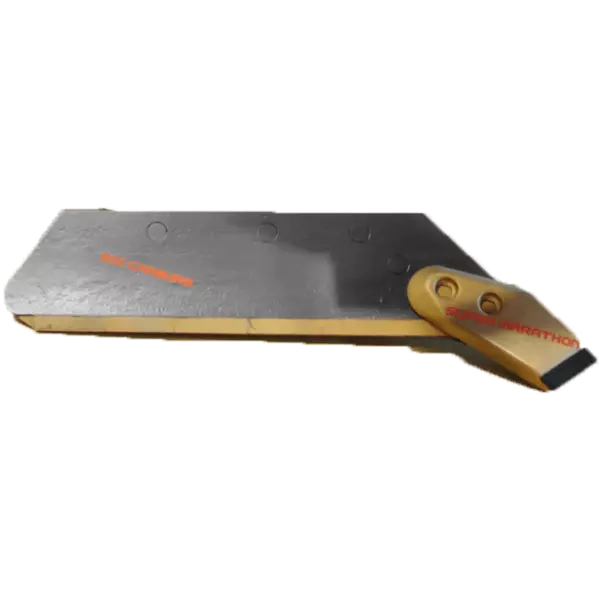

The technology of the TRIPLEX mouldboards with uneven layers is a KUHN exclusive. In combination with heat treatment, TRIPLEX increases the life of your mouldboard by 40%. Your KUHN plough equipped with TRIPLEX mouldboards with uneven layers ensures you one of the most attractive costs per hectare on the market!

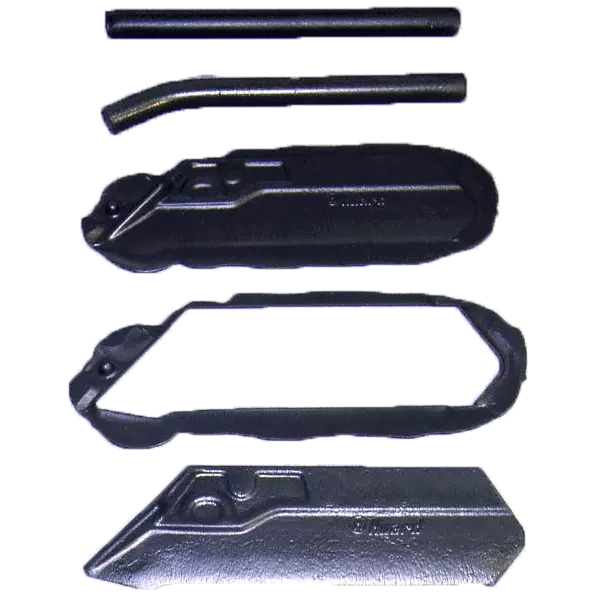

The wide landside on all the bodies reduces wear costs and improves the stability of the plough in soil.

The KUHN bodies are designed with a high and wide stem that ensures a clean cut of the furrow wall, while protecting the mouldboard and share.

The shares and points are forged and treated to provide maximum durability to your wear parts. The drop forging process increases impact and wear resistance by preserving the fibres of the material. The heat treatment significantly increases the life of your parts. Genuine KUHN parts are 20% stronger than standard parts.

The technology of the TRIPLEX mouldboards with uneven layers is a KUHN exclusive. In combination with heat treatment, TRIPLEX increases the life of your mouldboard by 40%. Your KUHN plough equipped with TRIPLEX mouldboards with uneven layers ensures you one of the most attractive costs per hectare on the market!

The wide landside on all the bodies reduces wear costs and improves the stability of the plough in soil.

The KUHN bodies are designed with a high and wide stem that ensures a clean cut of the furrow wall, while protecting the mouldboard and share.

The shares and points are forged and treated to provide maximum durability to your wear parts. The drop forging process increases impact and wear resistance by preserving the fibres of the material. The heat treatment significantly increases the life of your parts. Genuine KUHN parts are 20% stronger than standard parts.