A design focused on the operator!

The PRIMOR GII 110.1 Polydrive is one of the largest straw blower-feeders over 10 m3 in the world, and has been designed to have exclusive dimensions. It’s able to load 2 square bales of 2.70 m with the tailgate closed as well as 4 round bales of 1.80 m: a challenge met thanks to its 5.50 m body length behind the feed rotor. This length also corresponds to the exact width of two loader buckets side by side, making it easy to load silage. Its height of 2.67 m gives operators the best visibility on the market, while still fitting into the lowest buildings.

Its overall length of 7.68 m, which may seem large at first glance, does not compromise manoeuvrability thanks to the specific position of its axle (wheelbase of 5.60 m).

The V-shaped body makes top loading easier (particularly when loading silage). With a body width of 1.40 m at the conveyor and 1.65 m at the top, loading round and square bales from the rear is also made easier, with no risk of snagging.

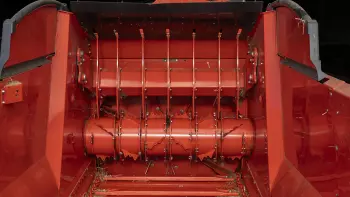

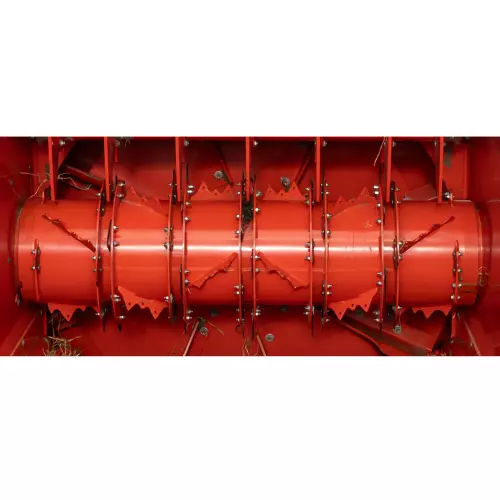

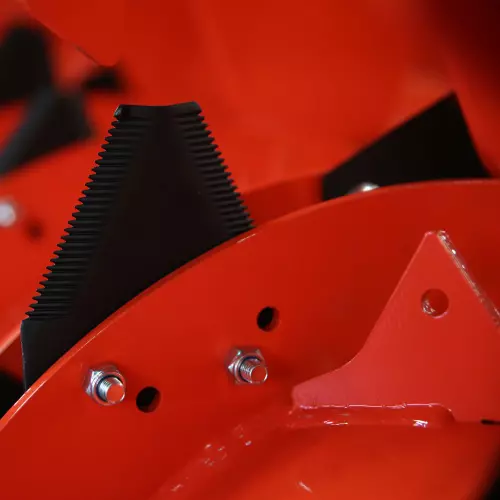

The optional patented UNROLL SYSTEM ensures optimal use of these large machines when working with multiple round bales. Available on all large KUHN PRIMOR straw blowers, the system uses two hydraulic clamps in the body to hold bales in place. The first bale being distributed unrolls freely, without being constrained by the waiting bales—a situation that often forces operators to move the conveyor forward and backward repeatedly. Once the bale has passed through the feeder, the operator releases the waiting bales to continue feeding or straw blowing. The added advantage of the UNROLL SYSTEM is that it allows the waiting bales in the body to be lifted, making it easy to remove strings or netting without effort.

Its overall length of 7.68 m, which may seem large at first glance, does not compromise manoeuvrability thanks to the specific position of its axle (wheelbase of 5.60 m).

The V-shaped body makes top loading easier (particularly when loading silage). With a body width of 1.40 m at the conveyor and 1.65 m at the top, loading round and square bales from the rear is also made easier, with no risk of snagging.

The optional patented UNROLL SYSTEM ensures optimal use of these large machines when working with multiple round bales. Available on all large KUHN PRIMOR straw blowers, the system uses two hydraulic clamps in the body to hold bales in place. The first bale being distributed unrolls freely, without being constrained by the waiting bales—a situation that often forces operators to move the conveyor forward and backward repeatedly. Once the bale has passed through the feeder, the operator releases the waiting bales to continue feeding or straw blowing. The added advantage of the UNROLL SYSTEM is that it allows the waiting bales in the body to be lifted, making it easy to remove strings or netting without effort.