,

5 m turning radius: easy handling!

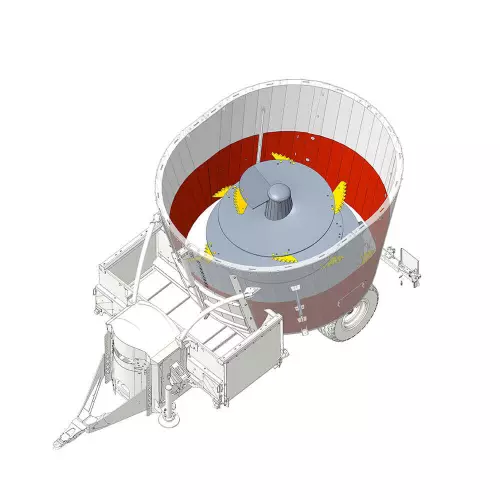

alleysThe design of the SPV Access - Power - Intense self-propelled mixers is highly innovative.

The steering axle is the rear axle. This allows for tight turns (5.9m). Turning around in the silos after loading or accessing narrow feeding passages is thus easy.

An optional front steering axle is also available for farmers who want even greater manoeuvrability. The turning radius of 5.00 m is thus the tightest in the market.

The rear axle is narrower than the front axle, which prevents riding over the freshly produced feed line. With a different wheel arch from the front axle, it evenly distributes pressure on the ground to protect the concrete soil in feed alleys and silos.

The steering axle is the rear axle. This allows for tight turns (5.9m). Turning around in the silos after loading or accessing narrow feeding passages is thus easy.

An optional front steering axle is also available for farmers who want even greater manoeuvrability. The turning radius of 5.00 m is thus the tightest in the market.

The rear axle is narrower than the front axle, which prevents riding over the freshly produced feed line. With a different wheel arch from the front axle, it evenly distributes pressure on the ground to protect the concrete soil in feed alleys and silos.