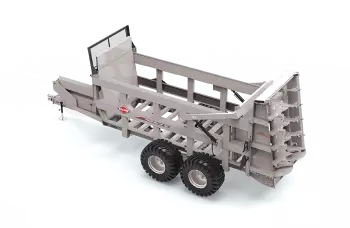

All-Steel Welded Construction

The all-steel welded ProPush® construction provides a solid framework and includes a reinforced tongue that pulls directly from the full-width axle. This results in a stronger, more dependable spreader since the unit is pulled from the axle rather than the front of the box.