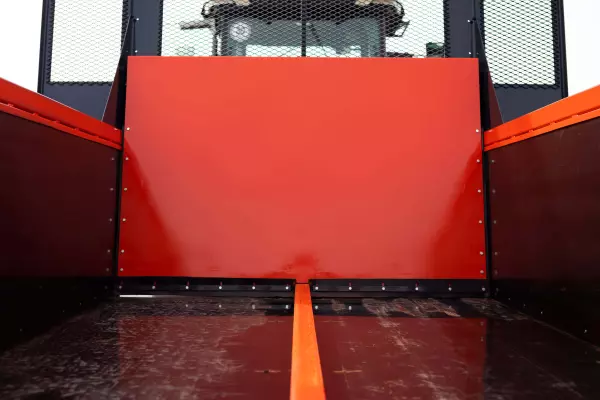

Proven ProPush ® Design

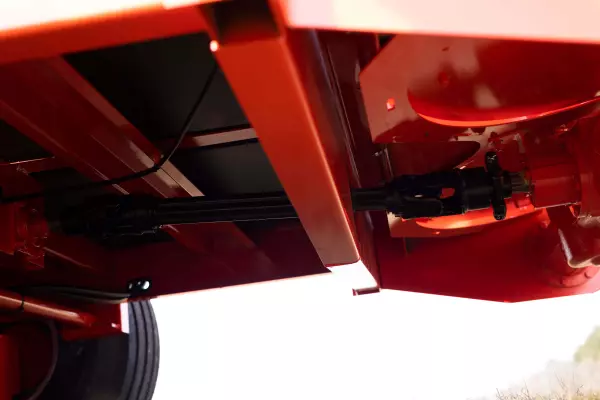

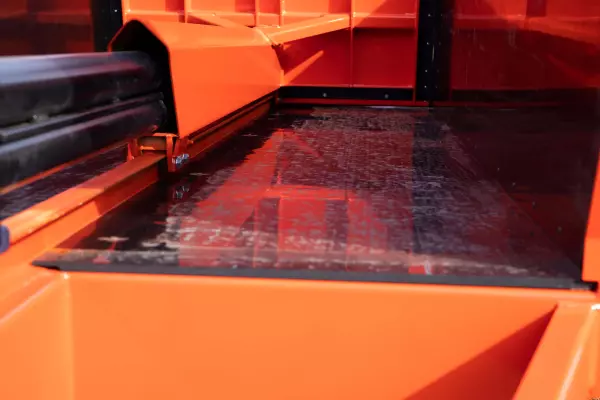

The ProPush box spreaders are designed with simplicity in mind. The hydraulic push-type design means no apron chains, fewer moving parts, faster unloading and dependable service life.

Download the Literature

ProPush Series (HP)