The DIGIDRIVE: the revolution

When KUHN invented this drive concept, tedding entered a new era.

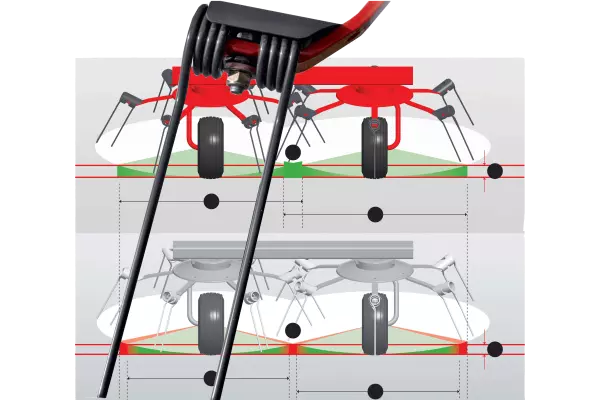

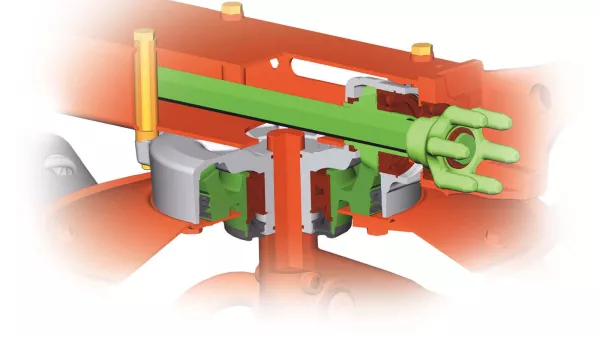

From this moment, it became possible to drive a very high number of rotors, to fold them with unmatched compactness and without any maintenance. A true revolution!

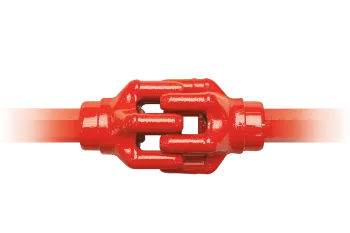

Since the launch of the DIGIDRIVE finger couplings 20 years ago, over one million rotors work fields throughout the world to ted forage with exceptional reliability. The DIGIDRIVE componants are manufactured from case-hardened steel and do not require maintenance.