Respect of road dimensions

Easy to use, the GA 6501 P and GA 7631 P can be easily handled even by the least experienced users.

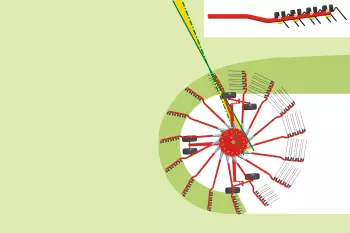

The transition from working to transport position is made hydraulically from the cab, without having to remove the rotor arms, saving time between plots.

During transport, the dimensions of the machines create a compact unit, which has the advantage to facilitate and secure movement on narrow roads or in urban areas.

Thanks to their compactness and manoeuvrability, these mounted models also allow access to small plots and narrow entrances.

The transition from working to transport position is made hydraulically from the cab, without having to remove the rotor arms, saving time between plots.

During transport, the dimensions of the machines create a compact unit, which has the advantage to facilitate and secure movement on narrow roads or in urban areas.

Thanks to their compactness and manoeuvrability, these mounted models also allow access to small plots and narrow entrances.