Multiple Delivery Options

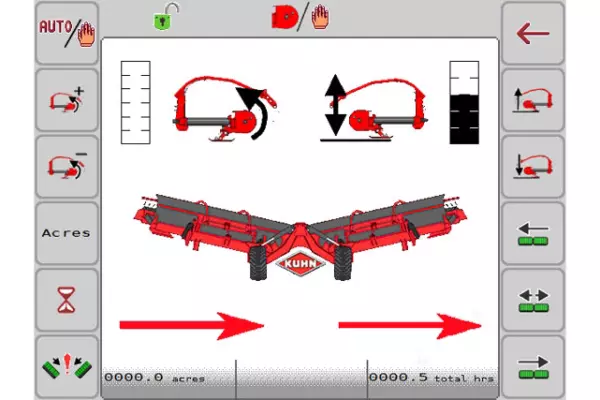

The MM 701 and 890 hay mergers can merge crop to the left, right, split or with either wing in the raised position. Both models have the ability to 50/50 split leaving all windrows with an even amount of crop for better harvesting efficiency. Having the ability to raise the wings independently is particularly useful for opening up fields, merging around field obstacles or cleaning up point rows in irregularly shaped fields.