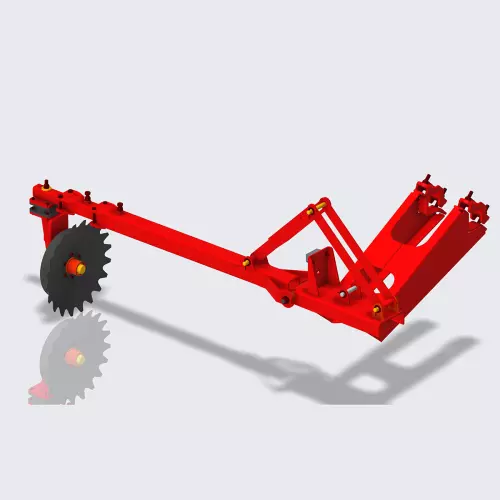

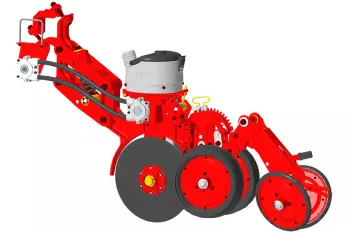

Units for planting large grains

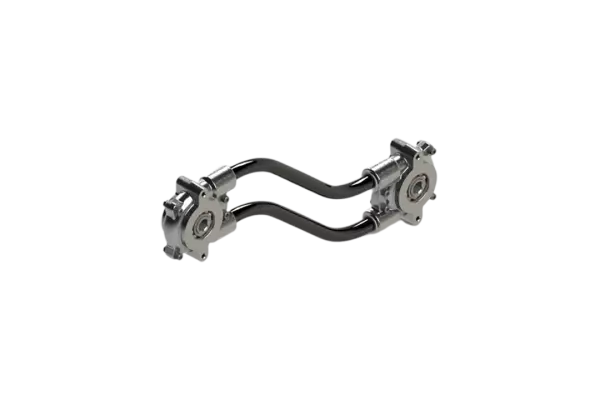

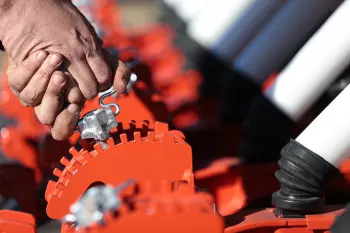

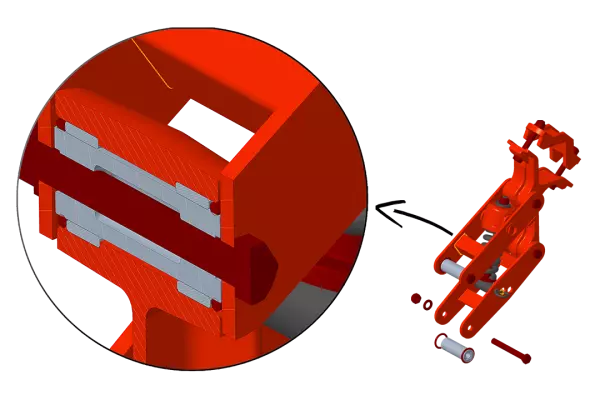

The SELECT seed drill offers all the precision of KUHN planters. Its pantographic planting units, both in the summer version for large grains and in the winter version for small grains, ensure great flotation regardless of relief, as well as correct fertilizer and seed delivery in the furrows. On the SELECT for planting summer crops, the seed unit is fitted with mini hopper, the metering unit with fluted disc and V-shaped press wheels. In addition, the SELECT has an 18" cutting disc, allowing fitting the fertilizer unit with double discs or blade, which offers total versatility for farmers. Added to all these factors, the speed and ergonomics for adapting the SELECT, provide the farmer with flexibility between seasons.