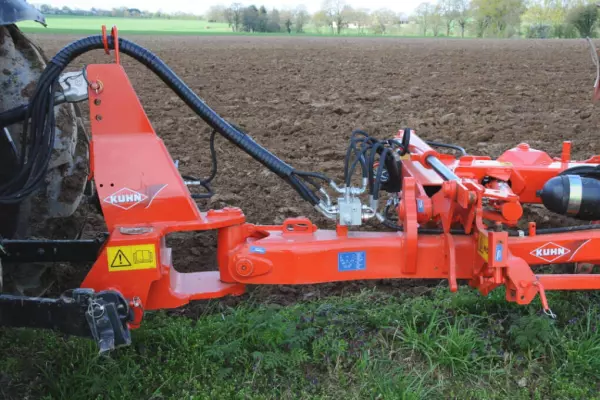

Economic performance

Investing in a VARI-MANAGER semi-mounted plough is the assurance of a profitable investment for your farm. The ultra-robust design and the quality of the materials used offer the VARI-MANAGER maximum durability. KUHN ploughs are known throughout the world for their reliability and quality of work, which gives them a higher resale value than other manufacturers on the market. In addition, TRIPLEX uneven-layer mouldboards and forged and treated wear parts extend the operating life by 20 to 40%! A range of carbide shares and points are available for more durability This results in a significant reduction in the maintenance costs of your VARI-MANAGER semi-mounted plough with less frequent replacement of wear parts.