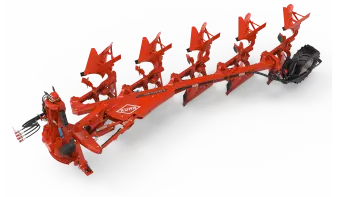

Control and comfort on the road with innovative headstocks

The result of 160 years of expertise in ploughing, the fixed headstock allows for quick hitching thanks to the fixed hitch arms, with simplified access for all operations. For transport, the GODRIVE oscillating headstock, combined with the WORK AND ROLL hydraulic wheel, allows safe travel at speeds of up to 40 km/h, with a steering angle of ±40°, comparable to a semi-mounted machine. The EASYDRIVE option completes this system by facilitating the transition from working to transport position without tools, thanks to the quick neutralisation of the top link. These systems are complementary and can be combined for maximum flexibility. Finally, the OPTIDRIVE suspension ensures smooth and safe driving on headlands, while storage in butterfly position during off-peak periods simplifies maintenance and reduces space requirements.