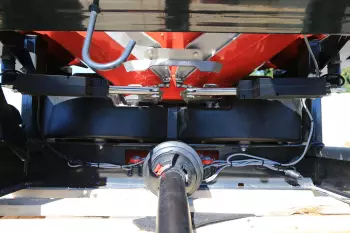

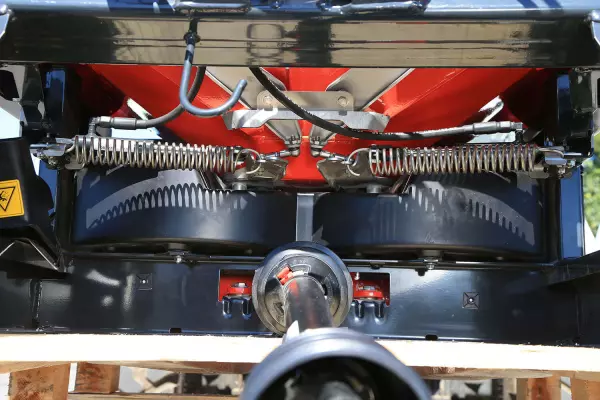

MDS spreading discs: (Multi-Disc-System), so much precision!

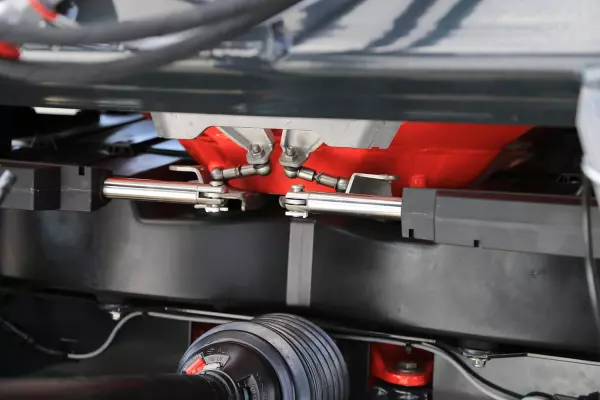

MDS (Multi-Disc-System) spreading discs are designed for standard or late spreading in high crops. They are simple to use and guarantee high precision with granular and organic (pellets) fertilisers, cover crop seeds and anti-slug pellets. According to the type of fertiliser and the working width, the length and orientation of the vanes can be adjusted. They are quick to adjust using the spreading chart. The discs are quick to remove, no tools required, for easy emptying. M1 discs come as standard for working widths between 10 and 18m. M2 discs enable working widths of 18 to 24 m depending on the product being spread, without impairing spreading quality, and improving yield on field borders.