CDA: unmatched accuracy

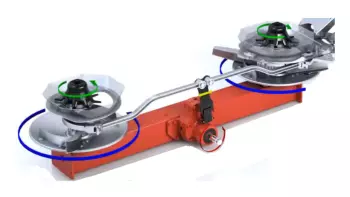

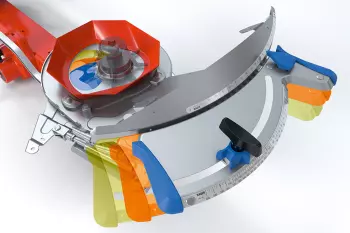

Different fertilizers, variable application rates, multiple working widths - your fertilizer spreader must adapt quickly to different needs. The coaxial distribution adjustment system - CDA, part of the Accura 1600 fertilizer spreader, helps address these challenges by providing easy adjustments. There are two important features that make the CDA system unique: ## NewLine##

- At the base of the hopper, the outlet allows quick adaptation to various fertilizers and working widths, adjusting the drop point of fertilizer on the distribution discs.

- Specially designed measuring sockets, close to the center of the discs, allow multiple supply points on the blades, ensuring a constant fertilizer flow and a uniform pattern. In addition, the working width of the Accura 1600 can be changed in a few seconds: just rotate the hopper base to change the fertilizer drop point on the disc. This operation is simple and does not require the use of tools.