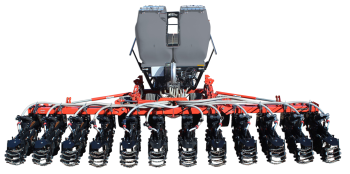

ST-PRO™ II Row Units

The row unit is the heart of the machine. ST-PRO II row units are easily adjusted without tools in a matter of minutes, allowing them to be quickly setup to suit field conditions and ensure continued superior strip formation from field to field. KUHN ST-PRO row units have no grease zerks, therefore require no daily maintenance further saving time and increasing productivity throughout the working day.