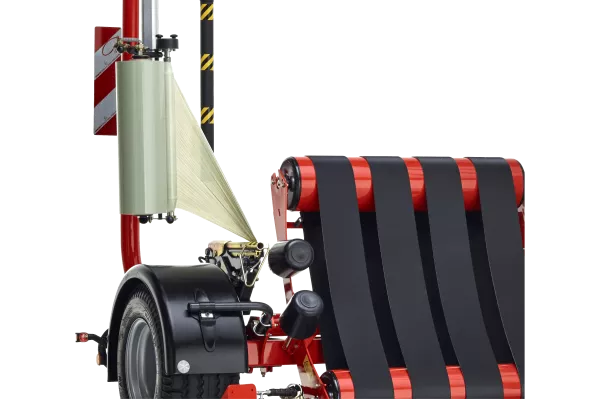

Mesa de encintado

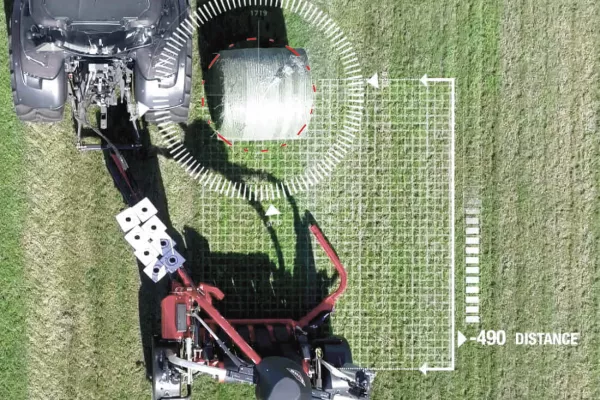

La mesa de encintado está provista de dos rodillos de accionamiento y cuatro correas con una amplia separación. Este diseño ofrece un asiento profundo y estable para la paca. Por su parte, dos grandes rodillos de sujeción de las pacas ofrecen una mayor estabilidad y guía. Las cuatro correas ampliamente separadas ofrecen máxima tracción y una rotación uniforme de la paca. Para conseguir un solapamiento óptimo del plástico garantía de una conservación óptima del forraje y de la preservación de la calidad durante el periodo de almacenamiento, resultando esencial que la rotación de la paca sea regular.