What is strip-till?

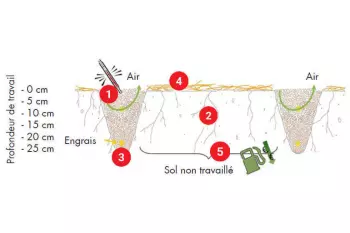

Strip-till is where only the future seed furrow is cultivated, preserving a layer of undisturbed residue in the inter-row. By working only in the seed furrow, you give the crop every chance of success just like a conventional preparation. In the inter-row, you benefit from the advantages of direct seeding: water conservation, supression of weeds, improved soil biology and reduced mechanisation loads.

Strip-till is defined by four points:

With the STRIGER 100, you accumulate the advantages:

Strip-till is defined by four points:

- Vertical tillage

- Cleaning of the furrow

- Fertilisation

- Preparation of the seedbed

With the STRIGER 100, you accumulate the advantages:

- Lower mechanisation costs with a reduction in working hours and less fuel consumption

- More economical use of fertiliser because it's placed exactly where you need it enabling you to reduce the dose

- Reduction in the use of weeding products thanks to the soil being covered with a layer of residue