One-piece chassis

Porter is a machine of different design, with a one-piece tubular encasing frame, a feature that contributes to reducing the equipment's weight and preventing residue build-up on its structure. The robust chassis also offers a frontward offset hitching point for easier coupling to the tractor.

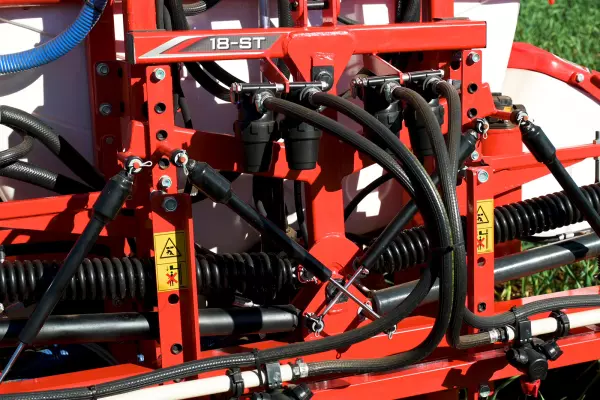

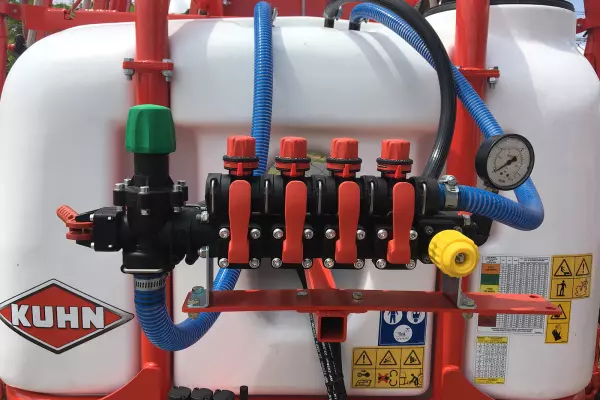

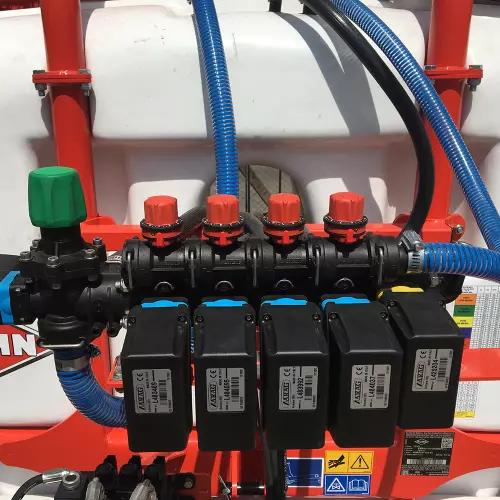

Due to the different configurations, it is possible to always stay close to the work actions, either with the approach of the spraying control, when manual, or by the panel, when electric. These are features that promote performance and comfort at the time of application.

They also increase the machine's service life.

Due to the different configurations, it is possible to always stay close to the work actions, either with the approach of the spraying control, when manual, or by the panel, when electric. These are features that promote performance and comfort at the time of application.

They also increase the machine's service life.