Well adapted to small-size tractors

The machine's limited weight, compactness and good stability contribute to its excellent behaviour even with small-size tractors. The low machine weight allows safe use by small-size tractors even on slopes.

| Working width (m) |

|---|

| Average windrow width (m) |

| Windrow deflector |

| Transport width with arms disconnected/connected * (m) |

| Windrow delivery |

| Guard deployment |

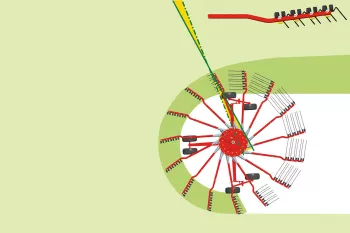

| Number of rotors / Rotor diameter (m) |

| Number of tine arms per rotor / Number of tines per tine arm |

| Tine arms |

| Gearbox |

| Bogie axles |

| Wheel type |

| Raking height adjustment |

| Tyres on each rotor |

| Hitch |

| Headstock |

| Headstock stabilisers |

| Theoretical tractor power requirement (kW/hp) |

| Road lights and signalling |

| Approx. weight (kg) |

| GA 3901 | GA 4201 | GA 4401 |

|---|---|---|

| 3.90 | 4.20 | 4.40 |

| 0.70 - 1.50 | 0.70 - 1.50 | 0.70 - 1.50 |

| Windrow curtain | Windrow curtain | Windrow curtain |

| 1.66 / 3.33 | 1.88 / 3.59 | 1.95 / 3.79 |

| To the right | To the right | To the right |

| Manual as standard - Hydraulic as optional equipment | Manual as standard - Hydraulic as optional equipment | Manual as standard - Hydraulic as optional equipment |

| 1 / 2.90 | 1 / 3.20 | 1 / 3.40 |

| 10 / 4 | 11 / 4 | 12 / 4 |

| Removable | Removable | Removable |

| Fully enclosed single reduction | Fully enclosed single reduction | Fully enclosed single reduction |

| As optional equipment | As optional equipment | As optional equipment |

| Fixed | Fixed | Fixed |

| By crank handle | By crank handle | By crank handle |

| 16 x 6.50 - 8 | 16 x 6.50 - 8 | 16 x 6.50 - 8 |

| 3-point Cat. 2 | 3-point Cat. 2 | 3-point Cat. 2 |

| Pivoting | Pivoting | Pivoting |

| 2 mechanical stabilisers | 2 mechanical stabilisers | 2 hydraulic dampers |

| 19 / 25 | 22 / 30 | 22 / 30 |

| As optional equipment | As optional equipment | As optional equipment |

| 520 | 560 | 610 |